Interfacings

INTERFACING is an extra layer that is attached to the back of your main fabric to give more body, to stiffen it and/or to stabilise it. Once it’s ‘backed’ onto the main fabric, it is then treated as one.

There are many different options and weights of interfacing, so to decide which one to use, think about what it needs to do…

You may want to stiffen something a little bit or even a lot, such as a collar and cuffs on a blouse compared to a mans formal shirt. You may want to give something structure so it can hold it’s shape and not collapse, such as a bag or maybe a sculptural piece of clothing. You may want to stop something stretching, such as a neckline or curved waistline. You may want to stabilise something but still keep the stretch, such as the neck line on a stretch garment.

It’s always a good idea to test some options on a piece of scrap first. If you have a small stock of various interfacings to experiment with, you can choose the best one for the effect you want. With clothing I prefer to start with less and build up, rather than using anything too heavy and rigid. The one I use the most when dress making in my classes is Vilene H180 fusible. It’s nice and soft so the fabric still behaves like fabric.

When using fusible interfacing, be careful not to melt it… you need the iron hot enough to melt the glue so it can fuse to the back of your fabric but its a fine line! To be safe you can use a pressing cloth but you can also press from the right side of your fabric if it can take a high heat.

I have taken the following information from William Gee, a family run haberdashery in London. I buy all my interfacings online from here and I have never been disappointed. https://www.williamgee.co.uk

It’s what’s on the inside that counts…

It’s an old adage that it is what is on the inside that counts, and when it comes to constructing a professional garment, it makes a huge difference to collars, cuffs, waistbands and more…

There are three main types of interfacing:

- Non – woven: made from fibres all pressed together it creates a fabric like felt or paper. It has no grain, so avoid wastage by cutting any which way. It offers a firm support and no flexibility. It also tends to be the cheapest option.

- Woven: have a grain and should be treated like other woven fabrics. They are more flexible and tend to be softer.

- Knit: are the most flexible of interfacing, they have two-way stretch and are used to add support without compromising the stretch of a fabric.

You can buy these as fusible (with glue you can iron-on) or sew-in; they come in various weights. Vilene is the biggest company that produces these fabrics and they tend to be the best quality.

With fusible interfacing make sure that you place the shiny side down on the wrong side of your fabric and iron. Try not to get glue on your iron as it ends up a big sticky mess that will transfer to everything you try to iron afterwards. Keep it clean with an iron cleaner stick. Or if you’re lucky and have a lot of space have a spare ironing board cover and iron just for these sticky jobs.

To take your garment to the next level, why not try some more traditional, high-end interfacings?

Silk organza: Used on lightweight fabrics to add body or “puff” so try it in sleeves for extra puff or as petticoats for full skirts (not as scratchy as net or tulle!) but it can also be used in collars and cuffs for lightweight support – think blouse not dinner shirt.

Top tip! Save your silk organza scraps and use them as ironing cloths. You can see through them and it will help reduce shine or burns caused by your iron on delicate fabrics.

Power net/tricot: A soft knit fabric that can offer some support to the wearer as well as the garment. Embrace your inner couturier and try inserting a corselette into a wiggle dress to smooth those lumps and bumps! If you are making a vintage dress why not try cotton bobbinette like the Dior “New Look” dresses

Horsehair: Not actually horsehair anymore, otherwise known as canvas (sometimes mixed with goats hair). This is usually used in tailoring for jackets and waistbands. Not ready for Saville Row yet? Try pad stitching a waistband on a skirt or trousers and notice the difference! Pad stitching is a form of stitching that attaches the interfacing to the main fabric. Through a series of long stitches you can help mould and shape the fabric. Time consuming but gives beautiful results.

Taffeta: Beautiful for silks or medium cottons. The stiffness of this fabric makes it great for interfacing.

Petersham ribbon: Do not confuse this with grosgrain. Petersham ribbon is stiff and ridged like grosgrain but the edge of the ribbon is bumpy and it can bend a bit like bias binding (whereas grosgrain can’t). This is excellent to use as waistbanding but also for waist-stays and supporting a neckline on a strapless dress.

SEWING LESSONS DURING COVID

I was going to post on how well my COVID-secure sewing lessons have been going when a second lockdown is announced in England!! This post is now all about how I am continuing my sewing lessons during covid. There’s always a way!!

SEWING LESSONS ON ZOOM

Lockdown means we’re all back to sewing on Zoom for the time being… not ideal but definitely workable. Some of my regular students who haven’t been comfortable to return to class in person have been attending via Zoom since May 2020 and so together we have found ways to make the most of it. It really is a great alternative if you can be open to a new style of learning.

Before booking a Zoom lesson, please bear in mind that it could be difficult for a complete beginner, especially a child, to learn with just verbal direction. I’ve made some very clear videos to help, but even so, I’ve found that some students need more hands on help to start with. Operating a sewing machine safely takes a certain amount of coordination, like patting your head and rubbing your tummy at the same time. Some people find this easy and some need more physical guidance. If you think you can manage that’s great, but if you’re unsure it might be better to wait till lockdown is over!

I’m keeping 1-2-1 sewing lessons via Zoom at the reduced price of £30 per hour for the time being as it can be restrictive. Private tuition is normally £40 per hour. I’m also offering a half hour slot for £15, which would be good if you just have a few questions or you want to try Zoom out.

Please go to BOOKINGS for more details.

sewing lessons after lockdown

As soon as we are allowed, I will return to teaching COVID-secure sewing lessons in person, following the government guidelines.

This is is what I have been doing to keep my sewing lessons safe…

- All new courses and children’s group classes have been cancelled until further notice.

- If either my students or I feel at all unwell or have been asked to self isolate for whatever reason, lessons are rearranged, cancelled, or attended via Zoom.

- Payment is due at the end of the lesson so if anyone needs to cancel there is no charge.

- Face masks are compulsory for everyone during the lesson.

- Large transparent screens divide the width of the table to protect those sitting opposite each other.

- A window can be left slightly open to ventilate the class room.

- I try to use verbal instructions only. If I really need to physically assist, I sanitise my hands before and after handling my students work.

- Medical grade hand sanitiser will be provided on entry and in the classroom.

- It’s not safe to share sewing equipment so if possible students bring their own scissors, pins, tape measure, un-picker, hand sewing needles, fabric marker etc. I can provide these if necessary but students will have to sanitise equipment before and after use.

- The classroom and sewing machines are thoroughly cleaned before and after each class. You are encouraged to bring your own sewing machine if you have one.

- The wash-room and all door handles are thoroughly cleaned immediately before each class. Paper towels are provided to dry hands.

COVID 19 RISK ASSESSMENT

| WHAT ARE THE HAZARDS? | WHO MIGHT BE HARMED AND HOW? | WHAT IS BEING DONE TO CONTROL THE RISKS? | WHAT FURTHER ACTION CAN BE TAKEN TO CONTROL THE RISKS? | WHO NEEDS TO CARRY OUT THE ACTION? | WHEN IS THE ACTION NEEDED BY? | DONE |

| Working with others | Myself Students | Considering the teaching space and any potential areas of risk. Reducing the number of students in a class/room.

Offering the option to attend classes in person or via Zoom. Postponing all new courses. |

To carry out my work, taking in to account the potential hazards and risks and where possible eliminate them or minimise the risk.

|

Myself | ||

| COVID 19

Limiting personal exposure |

Myself

Students |

Maintaining social distancing.

Using protective screens to separate students. All wearing masks face-masks for the duration of the lesson. Using hand sanitiser frequently. Not sharing equipment. Wiping down surfaces, chairs and machines before and after class.

|

Encourage students to bring their own sewing machine. | Myself; Students | ||

| Checking if I show symptoms | Myself | Following the Government & NHS advice.

Run classes via Zoom if necessary.

|

Myself | |||

| Checking if my students show symptoms | Students | Asking students to follow the Government & NHS advice.

No charge for cancelled lessons. Students attend via Zoom if they are unwell or are vulnerable.

|

Make sure students know the Government & NHS advice.

|

Myself | ||

| Maintaining cleanliness | Myself Students | Providing medical grade hand sanitiser at entrance/exit and in sewing rooms

Providing antivirus wipes in sewing rooms Cleaning sewing rooms before and after each lesson, with special attention to sewing machines, chairs and surfaces Cleaning entrance/exit, door handles and washroom before and after each lesson.

|

Hire a cleaner if necessary.

Remind students to use wipes and hand sanitiser before, during and after the class. |

Myself | ||

| Maintaining distancing | Myself Students | Reducing class size where possible and using two rooms when necessary.

Staying 2 metres apart where possible, or 1 metre with extra precautions in place. Using protective screens to separate students sitting opposite each other. Using verbal instructions and demonstration as much as possible. Limiting movement around the classroom.

|

Stay aware of keeping a safe distance from each other. | Myself; Students |

SEWING LESSONS VIA ZOOM

As Covid-19 has sometimes made it impossible to teach sewing face to face, ‘Sew Zoom’ lessons have become a fantastic alternative. I’ve been so pleased with how it’s worked for my regular classes that I’m going to continue to offer the option of Zoom sewing lessons from now on. I believe that for those with time or travel restrictions, it could be a real solution! You will of course need the use of a sewing machine and some other bits depending on what you are wanting to learn.

HOW IT WORKS:

Zoom is easy to use and it’s free! You don’t need a Zoom account to attend a lesson, you don’t even need to download the free app if you don’t want to… it’s up to you. All you need is a computer, iPad or mobile… the bigger the screen the better as we can see what’s going on more clearly. I also like to use Whatsapp along side Sew Zoom, to share close ups, instructions and videos.

If you know how to use Zoom that’s great, but if not, please don’t worry, I’m very patient and happy to show you the ropes! To start with, I’ll email you an invitation to attend a ‘Zoom Meeting’. Then on the arranged date and time you just click the link in the email under ‘Join Zoom Meeting’ and follow the instructions. It’s pretty simple, but if you’d like more detail, click HERE to watch a quick video by ZOOM which should help. Once you’re in the meeting I can explain more.

HOW TO BOOK:

I’m available to teach on Wednesdays, Thursdays and Friday afternoons. Weekends are only very occasionally available. Please email me to arrange a day/time. https://www.sewschool.co.uk/contact-helen/

Before booking a Zoom lesson, please bear in mind that it could be difficult for a complete beginner, especially a child, to learn with just verbal direction. I’ve made some very clear videos to help, but even so, I’ve found that some students need more hands on help to start with. Operating a sewing machine safely takes a certain amount of coordination, like patting your head and rubbing your tummy at the same time. Some people find this easy and some need more physical guidance.

COST:

Private tuition is normally £40 per hour, but because Sew Zoom lessons are restrictive I’ve reduced the cost to just £30 per hour. I’m also offering a half hour slot for £15, which would be good if you just have a few questions or you want to try Zoom out.

You can pay by PayPal or I can send you my bank details to make a transfer.

NHS DRAWSTRING BAG INSTRUCTIONS

Drawstring Bag Shopping List:

- 3 Metres of 150cm wide cotton fabric will make 4 or 5 bags.

- Cotton tape for the ties (3 metres per bag) Or… you could make these out of scrap fabric.

- Matching cotton thread

Cutting out:

- Cut two rectangles 75cm x 70cm per drawstring bag. Or… for the smaller size, cut two rectangles 60cm x 55cm per drawstring bag. The larger bags are preferable.

- Cut two 1.5 metre lengths of cotton tape per drawstring bag. Or… cut two lengths of fabric 6cm x 150cm

Making Up:

- The seam allowance is 1cm.

- The sides of the drawstring bag are 75cm / 60cm

- The top/bottom of the drawstring bag is 70cm / 55cm

- Make sure all the unfinished edges are finished with a zigzag stitch or an overlocker, if you have one.

- Pin the two rectangles right sides together.

- On one of the rectangles… mark the sides 6cm down from what will be the top of the bag, then mark 2cm down from that. You should end up with two marks each side.

- Leaving a gap between the two marks, stitch down both sides, seaming the back and front of the bag together.Leave the bottom open for now…

- Press these seams open and then from the right side, top-stitch either side of the seam to hold the seam allowance back.

- Now stitch the bottom seam and press. You can finish it like a french seam on the outside if you like

- We now need to hem the top of the bag to make a channel for the ties.

- Turn over and press the top edge by 1cm first and then another 4cm. The gap/holes you’ve left in the side seams should end up on the outside/right-side of the bag and in the middle of the folded back channel.

- Top-stitch this double fold down close to the edge and then top-stitch round the top edge for added strength.

- Using a safety pin, pass one length of the cotton tape in a hole at the side, all the way around the channel at top of the bag and out of the same hole. Tie the two ends in a knot.

- Do the same with the other length of cotton tape starting and finishing on the opposite side.

If you are making your own ties…

- Cut two lengths of fabric 5cm x 150cm

- Press the two short edges in by 1cm

- Press long edges in by 1cm so they almost meet in the middle and then press in half lengthways.

- Top-stitch all the way around the edges of this tie to make it nice and flat and strong.

IF YOU NEED ANY HELP PLEASE CONTACT ME…

https://www.sewschool.co.uk/contact-helen

GREAT STOCKIST FOR MATERIALS…

https://www.fabricland.co.uk/product/budget-cotton-tape-2-5cm-wide/

https://www.fabricland.co.uk/product/calico-fabric-300cm-wide/

FREE FACE MASK PATTERN & INSTRUCTIONS

FACE MASK

This Face Mask is 3 layers thick and has a pocket to put in a filter if desired. It’s a snug fit with wire to hold the shape over your nose. It is a generous size, giving a great amount of face cover and is cut with room to breathe.

Click HERE for the PDF pattern. When printed, the measurement between the points should be 21.5cm

For a simpler version of this FACE MASK, please click HERE to view my YouTube video.

Shopping List:

- 1 Metre of soft cotton fabric will make at least 10 x masks

- Approximately 0.75cm narrow elastic/cotton tape per mask

- 10cm wire per mask – you could use a pipe cleaner, garden wire, snap metal hair clips…

- Matching thread

- Interfacing is a good idea for added protection

Making Up:

- Cut x 3 using the Face Mask Pattern

- For added protection or if your fabric is a bit thin, iron some interfacing onto the back of one or more fabric pieces.

A FOOTS WIDTH SEAM ALLOWANCE

- Seam 2 pieces together along the top with a foots width seam allowance.

- With the other piece, fold the top edge over no more than 1cm and zig zag down.

- Open out the 2 pieces that you seamed together and fold in half the other way.

- Pin the curved edges right sides together, ready to sew.

- Do the same to the other piece.

- Stitch the curved edges with a foots width seam allowance.

- Open out the seams you have just stitched.

- Top-stitch these seams from the right side so that the seam is pulled flat and stitched down on to the seam allowance.

- Cut the wire and make sure the ends aren’t sharp by bending the wire or using sticky tape.

- Feed the wire through channel.

- Cut the elastic/tape in half, then cut each piece in half again… two for each side.

- Pin and sew the elastic/tape as shown on to the right side of the fabric. LOOK AT EDIT BELOW!!

EDIT

- Having worn the face mask out a couple of times, I decided it would be even more comfortable if I moved the position of the elastic/tape to the corners, coming out at an angle, rather than straight out of the sides. I have edited the pattern to show the elastic position.

CONTINUED…

- Take the pieces that were seamed together and fold them right sides out, along the straight seam so that they are the same shape as the piece with the wire in. Press carefully and top stitch this seam to keep it flat if necessary.

- This double piece slots, right sides together with the other, sandwiching the elastic between.

- Pin, with all the edges exactly together, down the side, along the bottom edge to and up the other side.

- Stitch together with a foots width seam allowance.

- Turn it all right side out and press nice and flat

- Top-stitch close to the edge, about 5cm along the top edge, down the side, along the bottom edge, up the other side and about 5cm along the top edge on the other side.

- The picture below shows the pocket where you could put a filter if so desired. The top elastics/tapes should be comfortably tied together and worn above the ears and the bottom elastics/tapes should be comfortably tied together and worn below the ears.

SEW ALTER – UPCYCLE YOUR CLOTHES

Learn how to Alter & upcycle your clothes

Over the last month, I’ve been making a real effort to dress in a more sustainable way. Clothes you buy are actually far too cheap. Those of you who know how much work goes into making a garment will agree that it is absolutely impossible to produce clothes for the price that many shops sell them at. It’s ultimately the seamstresses who get exploited. These skilled workers are being made to work for nothing while their employers get rich. It also makes self employed seamstresses feel unable to charge a fair amount for their work as people have got used to inexpensive clothing and textiles.

Not only is Fast Fashion unethical but it has been proved to be harmful to the environment. Huge quantities of unsold clothing goes to land fill because these companies make more money if they over produce but always have new designs to sell. The other issue is polyester clothing. Did you know that polyester is basically plastic and we all know how bad plastic is for the environment!

I have bought plenty of Fast Fashion in the past, which I will keep and wear because I don’t want to add to landfill, but there will be no more Fast Fashion for me! It’s actually a relief. There’s far too much choice in those shops, it takes ages to decide and then you always end up buying something that is not quite right because its cheap!

So from now on I will only upcycle and alter the clothes I own, or ones I have swapped with family and friends. Or, I don’t have a problem with buying second hand clothes to get creative with. And if I really want to treat myself to something new, I will either make it myself or pay the right amount for a garment that can be proved to be ethically and sustainably made.

Many of my students have said in the past “It doesn’t make sense to spend all this time and money on making something when I can buy it for a fraction of the price”, and to be honest I have always sort of agreed with them. Well not any more. I feel a renewed energy to teach as many people as possible how to be make their own clothes and also how to make the ones they own already, last for as long as possible.

So, all of this new thinking has lead me to design and add a new class called SEW ALTER. It’s all about learning some simple techniques to fit, mend or restyle your clothes. It will not only save you money but will also, in a small way, help to save our planet!

In a SEW ALTER session you will bring along a garment or two to alter or upcycle with my guidance. To get the most out of this class, you will need to have a good knowledge and confidence when using a sewing a machine so you can follow simple instructions and work independently. Please be realistic with your abilities as I can not teach you how to thread up and use a sewing machine in this session. It is only three hours long and there will be six students all needing different advice.

Below is a list of achievable alterations. Please note you may only get one of these alterations completed in the time depending on your ability and the amount of unpicking involved! Please do not bring items that are very expensive to practice on! To save time it would be a good idea to bring your clothes already pinned.

EXAMPLES OF ACHIEVABLE ALTERATIONS:

- Lengthen/shorten – sleeves, trouser legs or skirts.

- Take in/let out – waist, seams and darts.

- Alter a simple neckline.

- Remove/add – sleeves, collar, frills or other detail.

- Replace – zip, buttons

- Mend – rips, holes

Any additional fabric or haberdashery needed will have to be supplied by you.

These sessions will take place on a Saturday morning during school holidays from 10am till 1pm. All sewing machines and equipment are provided but you can bring your own machine if you prefer. The cost is £30.00

UNDERSTANDING THREAD TENSION ON YOUR SEWING MACHINE

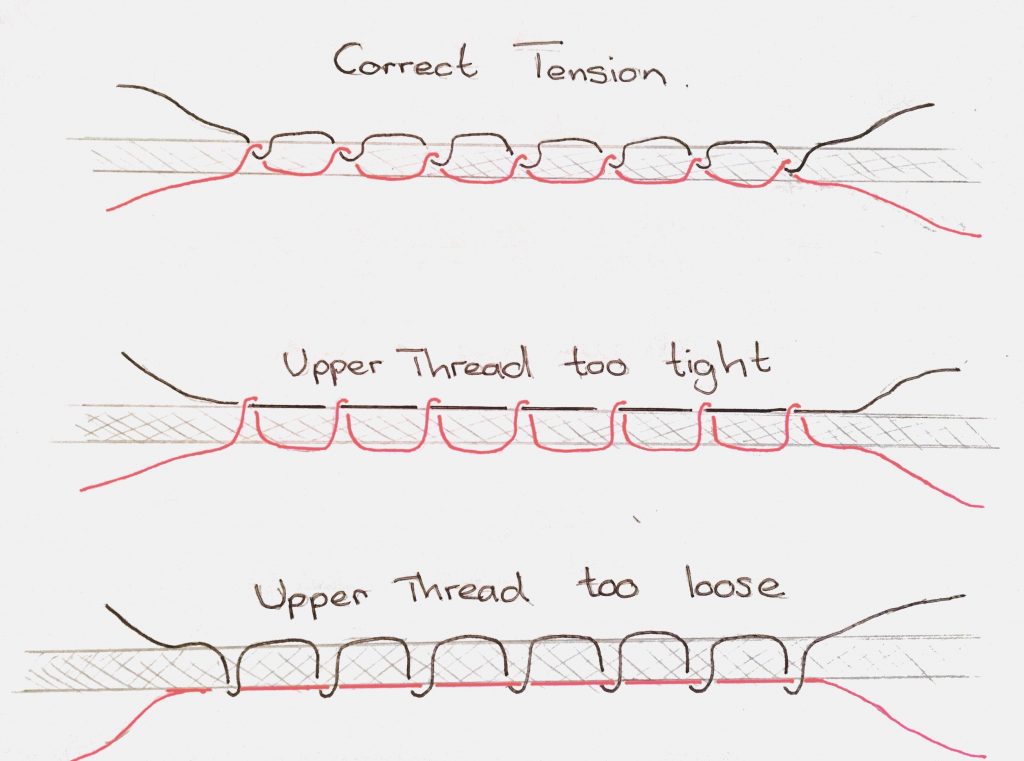

‘Thread tension’ is the resistance that you feel on the thread as it goes through the sewing machine. The perfect ‘thread tension’ will lead to lovely, flat and even stitches that look the same on both sides of the fabric. This perfectly balanced stitch is what you should try to achieve with all of your sewing projects. If your stitches are not like this, then you will need to find out why and correct the issue.

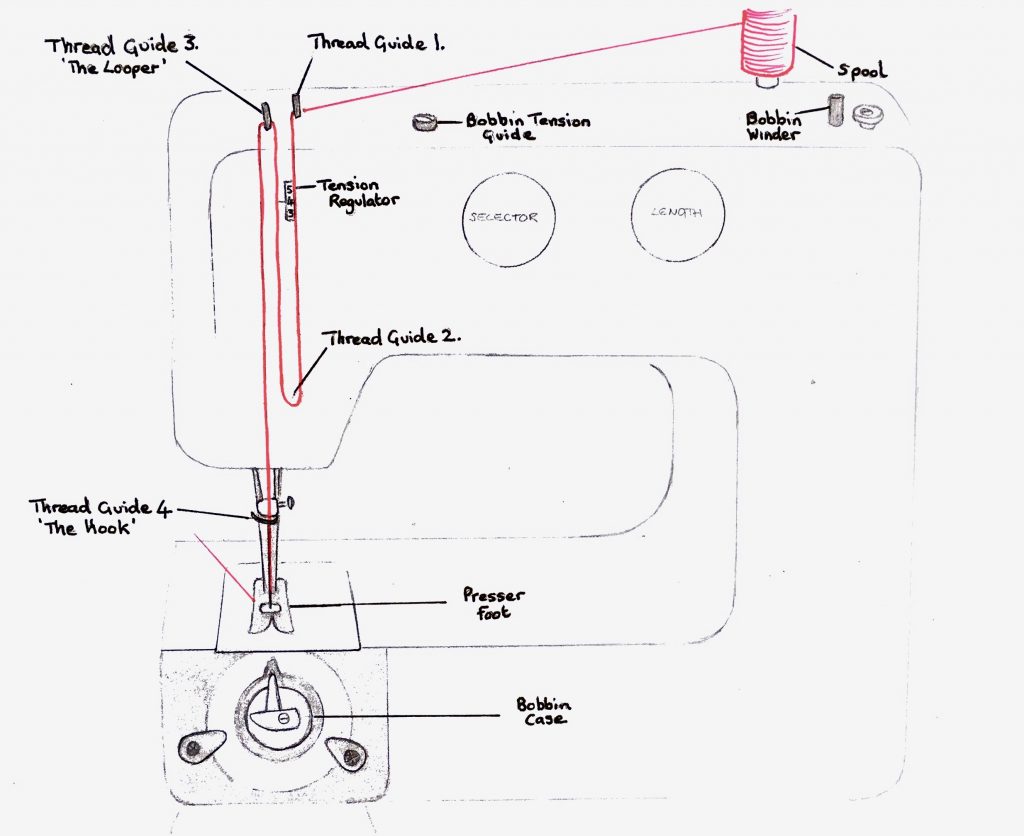

All sewing machines have a series of ‘tension devices’ to ensure that the top thread and bobbin thread have the tension they need to produce flat and even stitches. The most prominent of these is the tension regulator. You’ve probably noticed the tension regulator on your sewing machine. It’s usually a dial with the numbers 3, 4, and 5 highlighted or circled. This regulator tightens, or loosens, the tension discs that the thread passes down through before it goes up and through the looper.

There are many factors that can cause problems with your stitches, and so before you move the tension regulator you must first check a few things…

Incorrect threading is responsible for more tension problems than any other factor. If there is an obvious problem with your stitches, such as baggy, messy stitches that don’t hold the fabric together sufficiently, or tight stitches that ruche the fabric up, then you’ve probably not threaded your machine up properly. See if you can figure out whether the issue is with the top thread, or the bobbin thread, and go through the checklist below to see if you can fix it. If you can’t easily find the problem, then it is a good idea to unthread your sewing machine and thread it again!

- Did you use all thread guides? If the top thread comes out of the looper, you will get a big noisy mess! The hook near the needle really helps to stop the thread bouncing out of the looper as you stitch.

- Did you thread your top thread with the presser foot up? The tension discs, operated by the tension regulator, open when the presser foot is up, and close when the presser foot is down. If the top thread isn’t able to get between the tension discs, then it will have no tension and create a very loose top thread. Make sure the presser foot is up when threading the top thread.

- Is thread unwinding freely from the spool? If it is catching somewhere, it will lead to a very tight top thread.

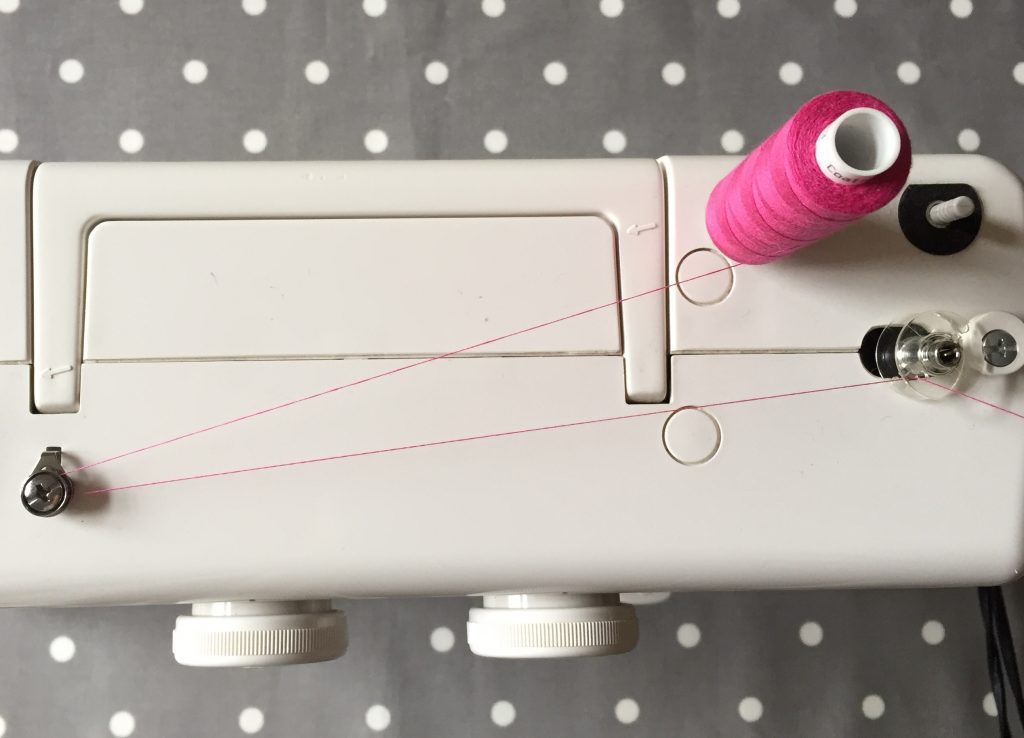

- Is the thread on the bobbin flat, and evenly wound? You must make sure you wind the bobbin using the bobbin tension guide. Messy bobbin = messy stitch!

- Is the thread unwinding freely from the bobbin case? Remove any thread from the outside of the bobbin, as it could get caught and stop its flow. This would create a tight bobbin thread.

- Is the bobbin inserted into the bobbin case correctly? If not, you will have a very loose and messy bottom thread. On front loading machines, make sure the thread is going clockwise as you drop it into the bobbin case. Also, the thread must go behind the flat bobbin-case spring, which squeezes the thread against the bobbin case as it comes out, creating the necessary tension for a flat stitch. This is a common mistake, so please check, even if you think you did it right! On a top loading sewing machine, check the bobbin thread has tension on it. If not, take it out and pop it in again, following the directions indicated.

Other less common factors could be…

Damaged machine parts… Check for rough or damaged surfaces where the thread passes through and could get caught. Some parts, such as needles, are easily damaged but easily replaced.

Clogged up Machines… This could restrict the flow of the thread. Fluff and thread ends can get stuck between the tension discs, under the needle plate, and around the bobbin/bobbin case. “Floss” between the tension discs, and check in the bobbin area and under the needle plate for fluff (lint) and thread ends.

Needles, threads, and fabrics… A needle that’s too large or small for the thread can effect the stitch because the size of the hole adds to, or reduces the total top tension.

USING THE TENSION REGULATOR

So, any major problem should be fixed by going through the checklist above, but to get a perfect stitch, you may still need to adjust the top thread tension using the Tension Regulator. Many sewers are nervous to touch the Tension Regulator, but actually it’s very straightforward. There is a way to adjust the bobbin tension too, but only if absolutely necessary!

First of all, to know which way to turn the tension regulator dial, you first need to inspect a sample of stitching on the default tension setting (number 4). It may help to have a different colour on the top thread, to the bobbin thread.

- If the bobbin thread shows on the top side of the fabric, the top thread tension is too tight (or bobbin thread is too loose).

- You can loosen the top thread tension, by turning the tension regulator dial a little towards a lower number.

- If the top thread shows on the under side of the fabric, the top thread tension is too loose (or bobbin thread is too tight).

- You can tighten the top thread tension by turning the tension regulator dial a little towards a higher number.

It is important to turn the dial a tiny bit at a time, as even a tiny turn makes a difference to the tension.

Adjusting the bobbin thread tension…

As I said before, you can adjust the bobbin tension too, but only as a last resort! This usually gets tweeked back to perfection when you get your machine serviced, and is unlikely to be the issue. However, for those of you who would like to know, you can adjust the bobbin thread tension by tightening or loosening the tiny screw that holds the flat bobbin-case spring in place and squeezes the thread as it comes out of the bobbin case. Again, it is important to turn the screw a tiny bit at a time as even a tiny turn makes a difference to the tension.

I hope this little blog has been helpful, and you can now understand how to get perfectly flat and lovely stitches! Happy Sewing x

HOW TO FOLLOW A COMMERCIAL DRESSMAKING PATTERN

So many of my students have all the skills needed for dressmaking but are apprehensive about following a commercial pattern because they look so complicated and wordy. They are wordy, but only because they are trying to give you all the information you may need. Much of this information is general stuff or irrelevant to the garment you are making. Once you have worked your way through a few patterns you will find it easier to skip to the bits you need.

My advice is…“Just have a go! What’s the worst that could happen?”

You may well make lots of mistakes, but, honestly, that’s one of the best ways to learn. I would recommend, however, that you use a cheap cotton to try out a garment… before cutting into anything special!

To help get you started I have put together a step by step list…

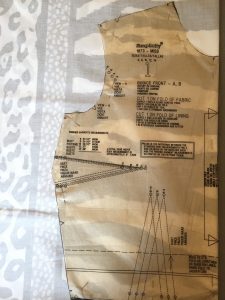

1. Work out your size…

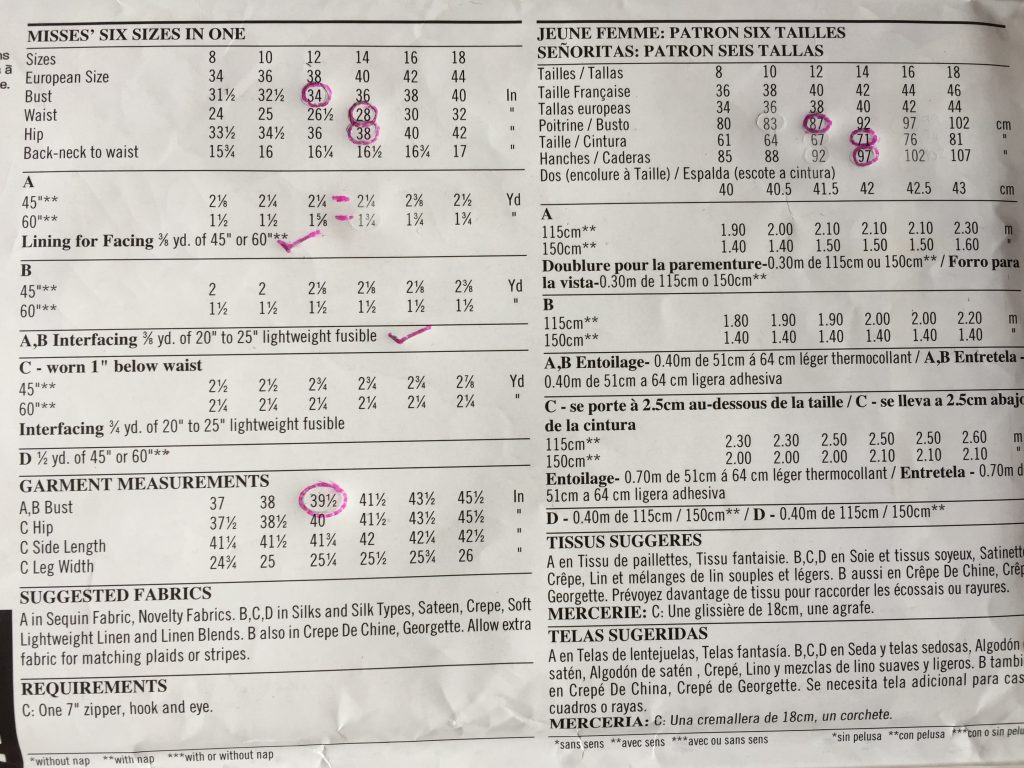

- Don’t expect to be the same size as you are in the shops! Unfortunately pattern sizes are usually bigger.

- You MUST measure your bust, waist and around the fullest bit of your hips. Find and ring these measurements on the measurement chart, which is usually located on the back of the pattern envelope but can sometimes be found on the pattern sheets. You will probably be a combination of sizes, which is fine.

- These measurements are usually offered in inches or cm. Inches are an English measurement and cm are used by the French. I prefer to use cm if possible as it is a smaller measurement and so more accurate.

- Also check the garment measurements. They can be found on the back of the envelope or on the pattern pieces. These are the measurements the actual garment will be. They are bigger than your size as they include a certain amount of ‘Ease’. Ease is added to give room to move but also depends on the design of the garment. Some garments, like coats, have a lot of ease and other garments such as a bodice has very little. If you prefer a slimmer fit, you can choose a size with less ease.

- To conclude this section… in the shops I am a size 10 but looking at the pattern measurements below my size is a combination of size 12 and size 14. Looking at the finished garment measurements, I would go with a size 12 as the pattern has lots of ease and I don’t like my garments too roomy.

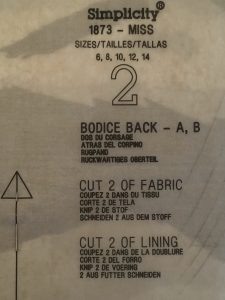

New Look Pattern by Simplicity

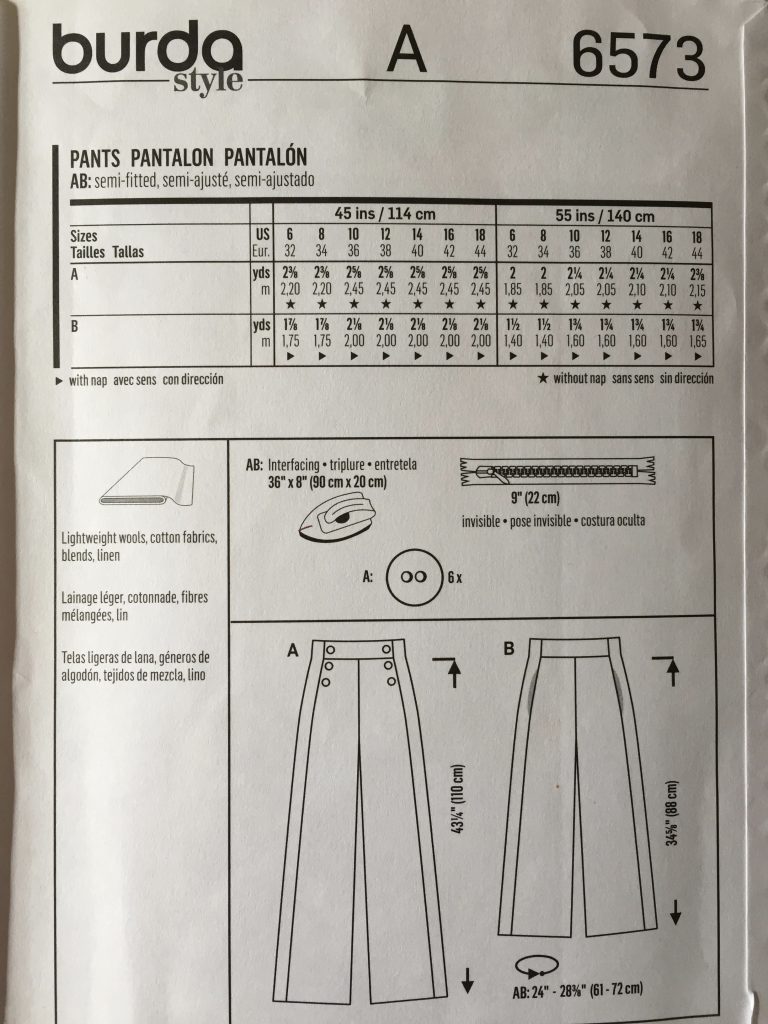

2. Use your size to work out how much fabric to buy…

- To work out how much fabric to buy, go to the size you decided on or the largest size you measured. Look further down the chart, on the back of the envelope and go to the style you want to make. Take a note of how much fabric you will need in each width.

- Fabric comes in two widths 45” /115cm or 60”/150cm This is because you may well need to buy more fabric if the fabric you want to use is the narrower width. Fabric amounts are usually given in metres/yards for each width.

- When choosing your fabric, pay careful attention to its thickness and how it hangs. Your garment won’t look how you’d expect it to look if you choose a fabric just by its appearance on the roll! Choosing the correct fabric is such a difficult thing to get right and will take practice. Dressmaking patterns generally suggest suitable fabrics so maybe go by those to start with.

- It is advisable to wash and press your fabric before you cut out or at least give it a good steam with the iron. This will help to avoid shrinkage.

- The pattern envelope will also tell you what else you will need, such as interfacing, thread and fastenings.

Burda Pattern

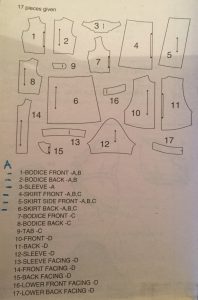

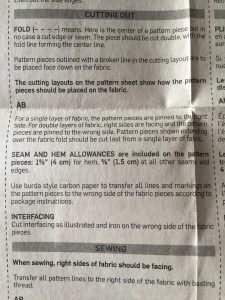

3. Cutting out the paper pattern pieces…

- Take everything out of the envelope and find the instruction sheets. Usually on the first page of the instructions there will be a list of pattern pieces. Work out, depending on the style you want, which pattern pieces you will need.

- You can cut out your pattern pieces directly from the pattern sheets or, if you think at some point you may want to make a different size, you can trace your size onto a separate piece of paper. You can buy pattern paper from Amazon or Ebay or you could use any thin paper as long as it’s big enough for the pattern pieces.

- Press the pattern pieces with a cool iron so that they are nice and flat. If you are a combination of sizes just move gradually and smoothly from one size line to another at the appropriate place.

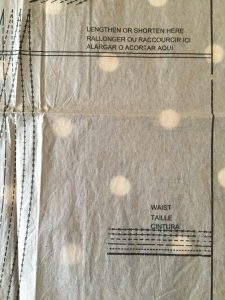

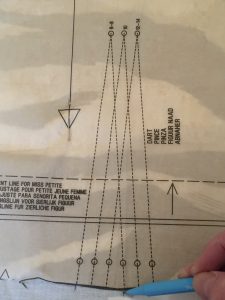

- At this point, if you haven’t already, you need to measure the length of your body… back neck to waist and also waist to desired hem length. Check it against the measurement chart. If the size you are cutting is longer or shorter than your measurement, there are places on the pattern where you can lengthen or shorten it. To lengthen, cut between the lines and add the necessary amount. To shorten, fold between the lines and pleat out the necessary amount.

Cynthia Rowley Pattern by Simplicity

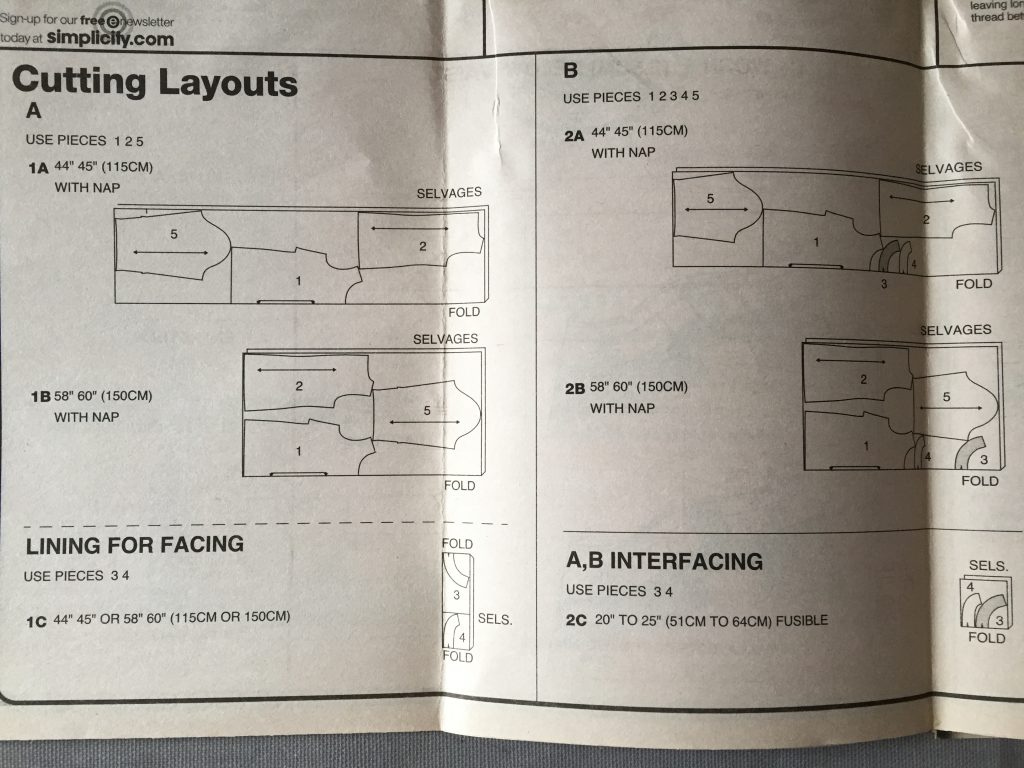

4. Cutting out the fabric pattern pieces…

- For help with placing your pattern pieces on the fabric, locate the relevant cutting layout in the instructions or on the pattern sheets. There will be several options depending on the style you are making and whether your fabric is 115cm wide or 150cm wide. Most cutting layouts are for fabric ‘WITH NAP’. This means the fabric has a direction, such as a pattern or shine. If this is the case, all the pattern pieces must be placed in the same direction from top to bottom down the length of the fabric.

- Most of the time you will be instructed to fold your fabric in half, with the right sides together, along the length. The selvages should be together with the fold of the fabric on the opposite side. This way you will end up with two of each pattern piece or one on the fold.

- Pay careful attention to keeping the pattern pieces straight by placing the double-ended arrow symbol (indicating the straight grain) parallel to the selvage. The selvage is the self-finished edge of the fabric that runs down the length on both sides. If this double ended arrow symbol is pointing to an edge it means you need to put this edge on the fold of the fabric.

- You must also take note of any other instructions written on the pattern pieces especially how many you need of each and whether you need one in lining & interfacing too.

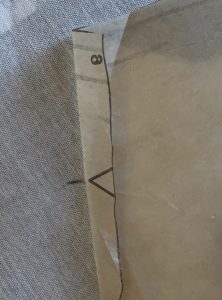

- All patterns have notches/balance marks on them. These marks match up on pattern pieces to be joined together so it’s difficult to sew the wrong pieces together or put in a sleeve back to front! You can cut triangles opposite the notches or mark the notch position underneath the pattern. I would never cut into the seam allowance.

- A lot of patterns have markings that will need to be transferred onto the fabric. These markings could be darts, pleats, pocket placement, zip or button holes etc. Depending on which side you’ll be sewing, some need to be marked on the wrong side of the fabric (darts/zip) and some need to go on the right side of the fabric (pleats/pocket placement/button holes) You can transfer these markings with a pencil, tailors chalk, thread or a special dressmaking transfer/tracing paper. Using a pencil or chalk is the quickest way as long as there aren’t too many marks! Chalk and thread come out if you are marking on the right side of the fabric.

Cutting Tips…

- When cutting out the fabric pieces, if you are right handed, cut with the pattern on your right so you can hold what are cutting off with your left hand. If you are left-handed do the opposite. Keep a bit of tension on the fabric you are holding but be careful not to pull it away from the pattern. Look at the ends of your scissors when you cut and try to keep the blade upright. To avoid jagged edges, stay in contact with the fabric as you open the scissors for the next cut by pushing them forward as you open.

- Keep the pattern pieces pinned to the fabric until you need them so you don’t forget what they are!

5. Sewing the garment together

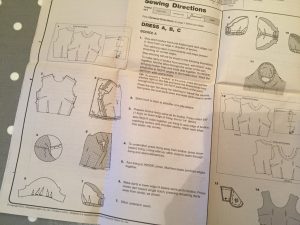

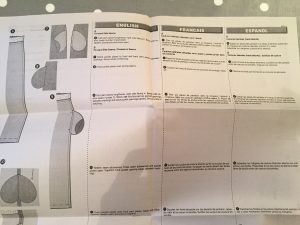

- Find the step-by-step instructions on how to put your garment together. They are mostly found as folded paper sheets. They will be numbered and accompanied by diagrams.

Simplicity Burda

- These instructions may jump from one style to another, which can be a bit confusing. I find it helps to somehow highlight all the information relating to your style. You will be relieved to find that many of the instructions are not relevant to you.

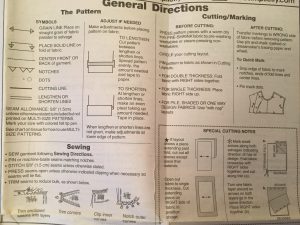

- Before you start just check your seam allowance. A 1.5cm seam allowance is normally included in the pattern but just double check this in the General Directions. These are usually found on the first page of the instructions.

Simplicity Burda

- Unless what you’re making is fully lined, you will need to decide on how you are going to finish off the seam allowance. You must do this as you go along because it’s impossible to do to it all at the end. I have listed the most common ways below…

Zigzag over the edge. It’s the quickest way on a regular sewing machine.

A French seam looks really neat if your fabric isn’t too thick.

Using an Overlocker is really quick and neat if you’re lucky enough to have one.

- Now it is time to follow the step-by-step instructions. If you get confused whist following these at home it will help to google the task in hand… whether it be understitching, setting in the sleeves, attaching a waist band or facing, binding the arm holes, etc

GOOD LUCK!

If you get completely stuck, book yourself a private lesson with me! :o)

How to Sew Stretch Fabrics on a Basic Sewing Machine

As you may know using an Overlocker is the fastest and neatest way to seam stretch fabrics but these are expensive and take up valuable space in your home. I have collected together some essential information to help make sewing stretch fabrics on a basic sewing machine a successful experience!

First of all here are some terms you will hear when dealing with stretch fabrics…

2-way stretch fabric

Fabric that stretches across the width but not the length

Common in dress making fabrics for it’s comfort!

4-way stretch fabric

Fabric that stretches across the width and the length

Common in garments such as swimwear, active wear, and dance wear.

Memory

How much the fabric stretches and if it goes completely back after it has been stretched.

Stretch stitch ‘+.S.S.-‘

A style of stitch that will not snap when stretched.

Needles

You must use either stretch or ball-point machine needles when sewing stretch fabrics. Because these needles part the fabric they don’t make holes where as universal needles can leave holes in some woven fabrics. They can also miss lots of stitches in very stretchy fabrics making it impossible to sew a seam.

You can use either ball-point or stretch needles for most projects but only stretch needles work when sewing very stretchy 4-way stretch fabric.

Another needle you may like is a stretch twin needle. This needle is commonly used to hem stretch garments. It sews two parallel lines on top with a zigzag underneath and will give your finished hems a lovely professional look.

Stitch & Thread choice

Stitch choice plays a big part when sewing stretch fabrics. Because regular polyester thread doesn’t stretch but the fabric does you could end up with the thread snapping and holes in your seams! It is therefore necessary to use a stitch that stretches… unless you use a stretchy thread… more about that later!!

There are a few stretch stitch options you can use and you will need to practice these stitches in order to find the one that work best for your project. Below are a few of the most common stitches. Please look at the instruction manual to identify these stitches on your sewing machine.

Zigzag stitch is the most common. Adjust the stitch width and stitch length to get the right stitch. It needs to be as narrow as possible with a small stitch length to get the stretch.

Triple Stitch is a ‘stretch stitch’ and will be located at the top of your stretch stitch selection. It is basically a back-stitch… 2 stiches forward and 1 back, which works well but must be used with caution, as it is bulky and can distort the fabric. Triple Zigzag Stitch may be necessary when sewing super stretchy 4-way stretch fabrics! Again you will find it at the top of your stretch stitch selection. This is also a backstitch but a zigzag version and so it can also be rather bulky.

Over Edge Stretch Stitch is the domestic machine’s version of an overlocking stitch so if you want an overlocked look and small seam allowances this is the one to use. This is quite a time consuming process, as you have to cut away the excess seam allowance after sewing each seam.

Maxi lock stretch thread

There is now this amazing stretchy thread from America, which is available on Amazon. It is pretty expensive so I have just bought the Eggshell and Black colour to start me off.

This stretch thread is easy to use. You can wind a bobbin and thread your machine like normal. For sewing, set the stitch length to 3, and the tension to 4.5. You can then stitch a regular stitch… As the actual thread will stretch, the stitch doesn’t have to! Of course, you can still use a stretch stitch if you want to… all of the stretch stitches perform even better when you use stretch thread.

Finishing the Seam Allowance

Stretch fabrics tend not to fray so it is not always necessary to finish the seam allowance. If you want to make the seams extra secure or flat you can zigzag the seam allowance together as you normally would.

Exceptions

- With a 2-way stretch fabric you can usually stitch down the length as normal because the fabric doesn’t stretch down its length, only across its width.

- You can sometimes get away with just loosening the tension on slightly stretchy fabric, as this will give the stitch a little slack/stretch. I do this when top stitching a wider neckline or armhole that doesn’t need to stretch much as I prefer the look.

- When you are sewing something non stretch like interfacing, seam tape or trim onto a stretch fabric you can use a normal stitch. It helps, where possible, to sew with the no stretch on top.

Use a Walking Foot

If you use a regular presser foot, which presses down on the fabric as it’s fed through the sewing machine, the fabric will stretch and the stitches will hold that stretch in place. The best way to stop this from happening is by using a Walking Foot. This foot bounces up and down while you sew, which is a bit off putting to start with but it works brilliantly with stretch fabrics. It’s also great for quilting, as well as sewing velvet and slippery fabrics that never seem to stay where they have been pinned! This is because the presser foot pushes these more challenging fabrics out of place! The Walking Foot is honestly one of the most useful feet I have ever bought. I absolutely love it!

Also known as an Even Feed Foot, the Walking Foot is quite expensive but if you plan to sew a lot of stretch fabrics and don’t want to buy an Overlocker I would really urge you to splash out and buy a Walking Foot.